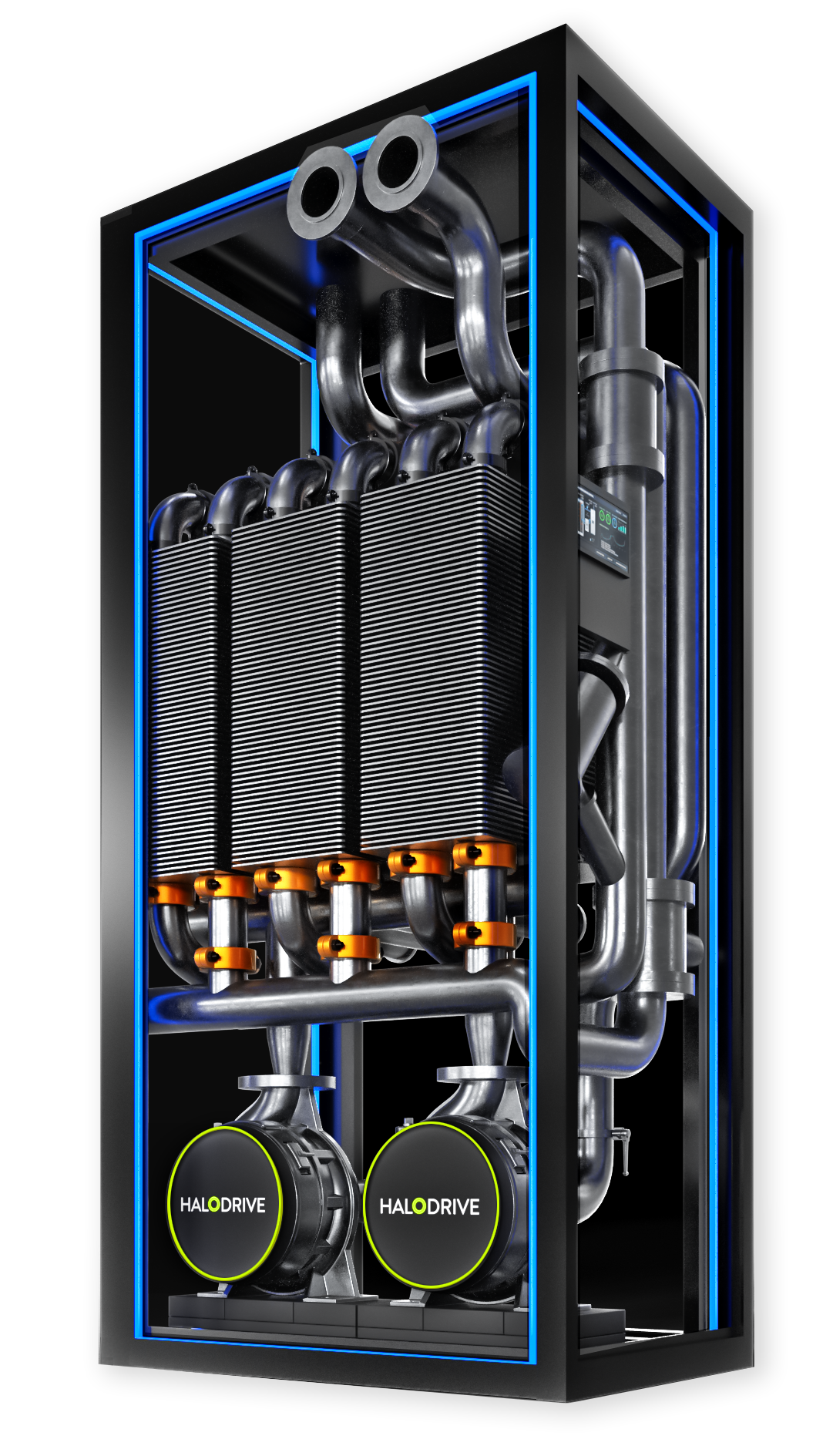

The HaloDrive™ Cooling Engine is a purpose-built thermal platform for the AI era—engineered to eliminate bottlenecks, slash energy waste, and unlock new levels of sustainable performance. By replacing inefficient mechanical cooling architecture with a rare-earth-free, ferrite-based axial-flux motor-pump system, it transforms cooling from a parasitic load into an active energy asset, delivering 80–90% wire-to-fluid efficiency and up to 2 MW of direct-to-chip cooling in a compact, modular footprint.

Designed for next-generation AI, HPC, and OCP/Deschutes-class data centers, the Cooling Engine combines propulsion-grade electrification with bidirectional SiC inverter-based DC grid integration—capturing energy that legacy CDUs waste and returning it to the system like regenerative braking in an EV. This breakthrough approach reduces operating costs, improves sustainability, and strengthens long-term supply-chain resilience by eliminating rare-earth dependencies.

With robust modularity, high reliability, and support for advanced DC microgrid ecosystems, HaloDrive enables hyperscale operators to scale faster, reclaim rack-level space and power for compute, and save millions annually—setting a new benchmark for efficiency in high-density AI data centers.

The HaloDrive Cooling Engine is engineered for efficiency, sustainability, and the compute demands of today and the future.

“In the AI era, whoever controls the heat, wins.” -Global Data Center Data Hub, 9-18-25

Economic Impact

CapEx savings: Up to $4.7 M for a 20 MW data hall (17–28%)

Annual OpEx/grid revenue uplift: $1.9 M

Payback: ~1.5 years

IRR: 34–38%

Compute Uplift

+15% more GPUs (Graphic Processing Unit) per kW by reclaiming cooling overhead for IT load

Redefines Environmental Performance

Cutting chiller energy use by up to 80%

Reducing CO₂ emissions by up to 40% compared to traditional liquid cooling

Avoiding rare-earth supply chain volatility through the use of Ferrite-based materials

Cutting water use by 75-80% per 20 MW facility, further enhancing sustainability and cost savings

Compact Power. Massive Cooling.

Orbis Electric’s Cooling Engine sets a new benchmark in data-center thermal efficiency, sustainability, and modularity. With propulsion-grade ferrite motors, SiC power electronics, and intelligent digital controls, it delivers:

2 MW modular cooling capacity

80–90% wire-to-fluid efficiency

34–38% IRR with sub-2-year payback

Fully compliant with OCP Deschutes and DOE OCED standards, it enables waterless, rare-earth-free, carbon-neutral cooling for the next generation of high-density AI data centers.

System Architecture & Controls

Integrated motor-impeller assembly minimizes pump losses, maximizing wire-to-fluid conversion

Bidirectional SiC inverter enables dynamic load balancing, energy recovery, and DC grid export

Self-tuning controls with digital twin modeling for adaptive fluid balancing, predictive maintenance, and anomaly detection

Supports native 400 V DC bus integration with market DCIM/BMS platforms

Cybersecure remote monitoring, OTA firmware, and data logging

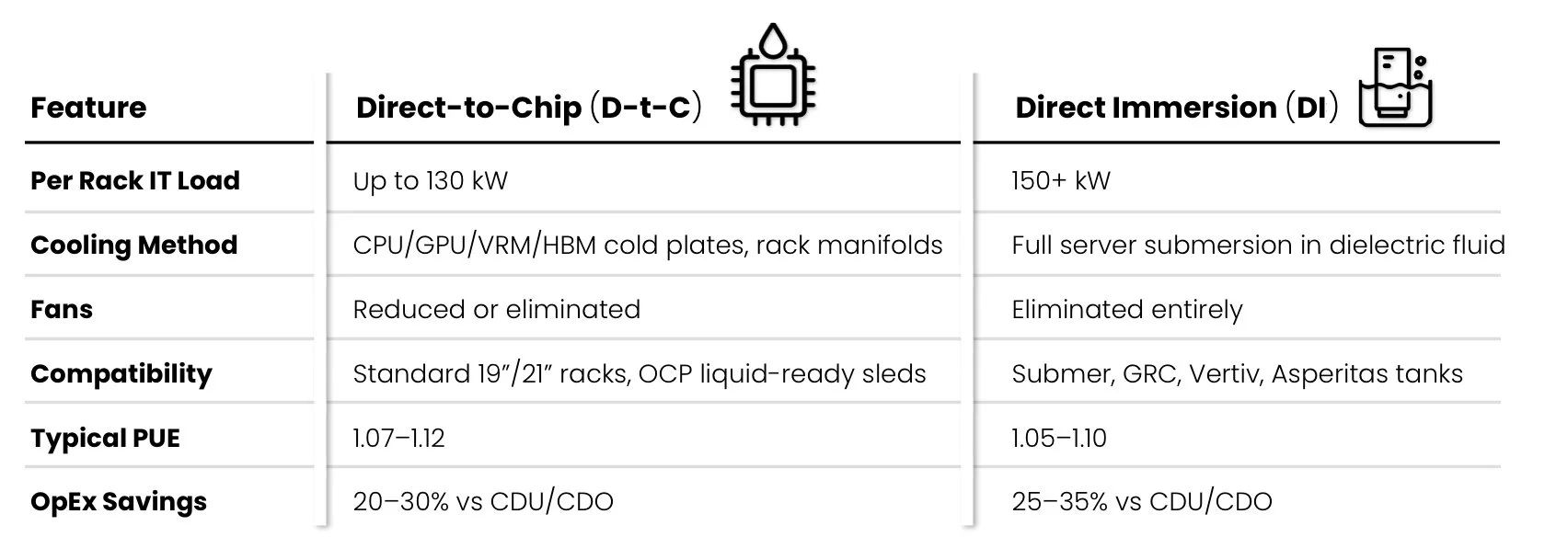

Scalable, sustainable, and flexible for both Direct-to-Chip and Direct Immersion architectures

The HaloDrive Cooling Engine supports two high-efficiency cooling paths: Direct-to-Chip (D-t-C) for retrofit and cold-plate deployment and Direct Immersion (DI) for ultra-dense, fanless AI clusters.