Purpose-Built Thermal Power for AI and Data Centers

When HaloDrive morphs into a motor-pump configuration, it becomes the HaloDrive Cooling Engine— a next generation thermal platform built for extreme heat loads and continuous operation.

Re-Engineering Cooling for the Moment it Matters Most

The HaloDrive Cooling Engine transforms cooling from a passive facility utility into an active, high bandwidth thermal platform engineered for AI workloads, DC-native power, and the next generation of high density compute.

As AI infrastructure pushes beyond traditional operating envelopes, cooling can no longer be static, oversized, or slow to respond. Cooling Engine is purpose built to operate at the speed of modern AI systems, delivering precise thermal control exactly when and where it is needed.

lower energy use

higher compute density

reduced water dependence

native alignment with emerging 800 VDC AI power architectures

Why Cooling Engine is Different

Conventional liquid cooling systems were designed for predictable, steady state operation. They rely on high flow rates, oversized pumps, and conservative safety margins to maintain stability — increasing energy use, hydraulic inertia, and response latency.

Cooling Engine was designed from first principles for AI factories, where:

Utilization fluctuates rapidly

Thermal conditions change in milliseconds

Power architectures are shifting toward DC-native designs

Instead of over circulating fluid, Cooling Engine uses control authority, higher allowable ΔT, and fast response to deliver stability efficiently— without excess flow or wasted energy.

Built for 800 VDC AI Power Architectures

Cooling Engine is natively designed for emerging 800 VDC data center environments, aligning directly with modern HVDC power stacks.

What this enables:

Elimination of intermediate AC conversion stages

Reduced electrical complexity and parasitic losses

Clean integration with DC busways, power electronics, and energy-storage systems

Isolated pump power domains for fault containment and improved reliability

Carry-Through Capability: Zero-derate cooling through failure or maintenance, enabled by instant electronic load transfer.

Cooling that fits naturally into next-generation AI power architectures — without forcing legacy AC systems back into the stack.

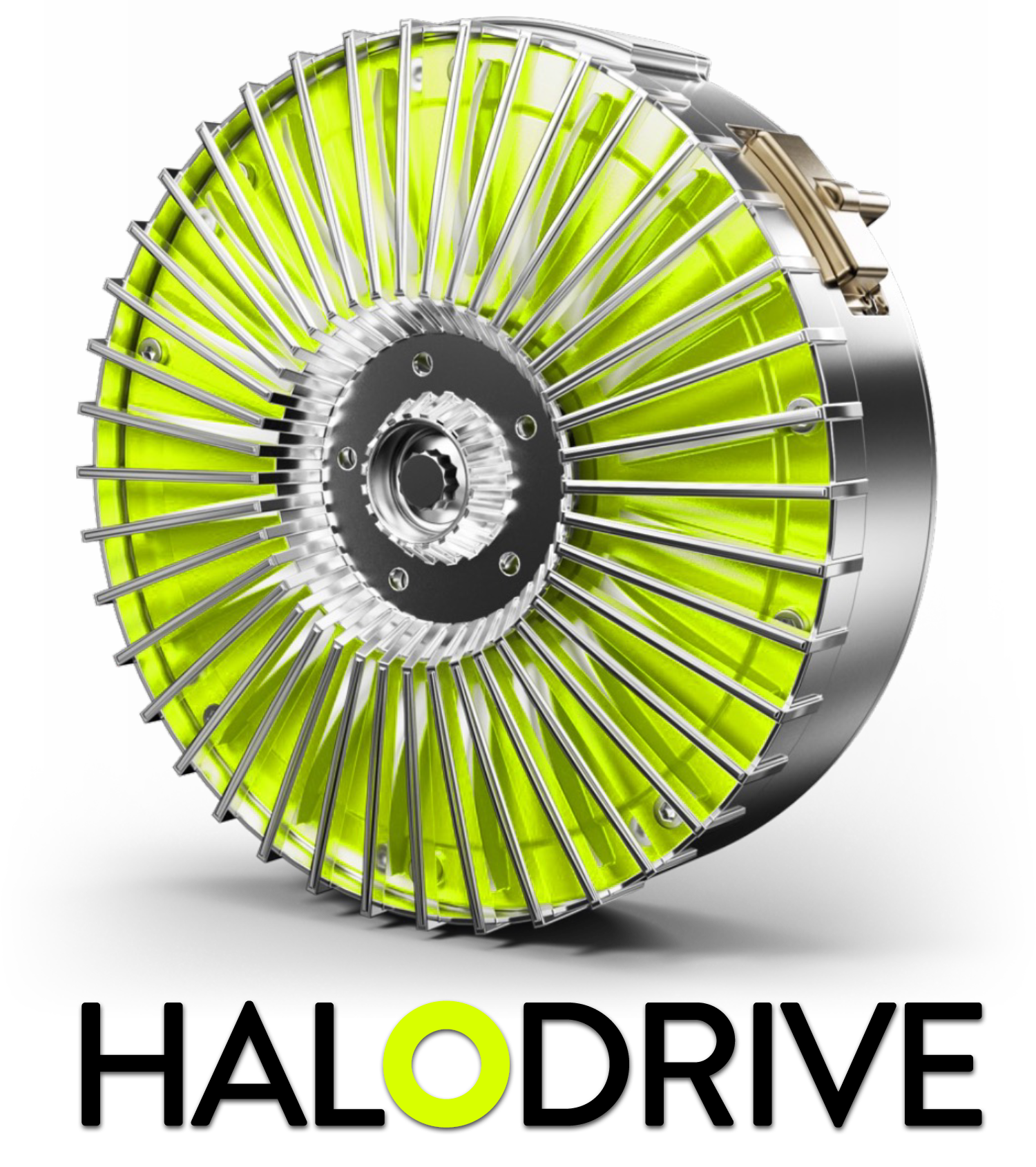

Propulsion-Grade Architecture at the Core

At the heart of Cooling Engine is HaloDrive™ — a propulsion-grade architecture originally developed for aerospace and automotive applications, where efficiency, precision, and reliability are mission-critical.

Core architecture:

50 kW axial-flux permanent-magnet motor

Axial magnetic (sealless) pump

Magnetically coupled, leak-free operation

Why it matters:

High torque density enables compact, high-power operation

Low rotational inertia supports rapid, precise response

Sealless design improves reliability and eliminates leak paths

By applying this architecture to thermal infrastructure, Cooling Engine brings mobility-class performance and control into the data-center cooling stack.

High-Bandwidth Control of Flow and ΔP

Cooling Engine prioritizes control authority— not brute force circulation.

It actively regulates flow and differential pressure (ΔP) as first class control variables, enabling:

Fine grained modulation of flow and ΔP

Stable operation across wide turndown ratios

Rapid response to workload-driven thermal transients

Result: Pump energy closely tracks real IT load, reducing over-cooling margins while maintaining tight thermal envelopes at the cold plate

Higher ΔT, Lower Flow — by Design

Cooling Engine is designed to move heat, not water.

Instead of minimizing ΔT through excessive flow, it operates intentionally at higher allowable ΔT in the secondary loop.

Key design advantages:

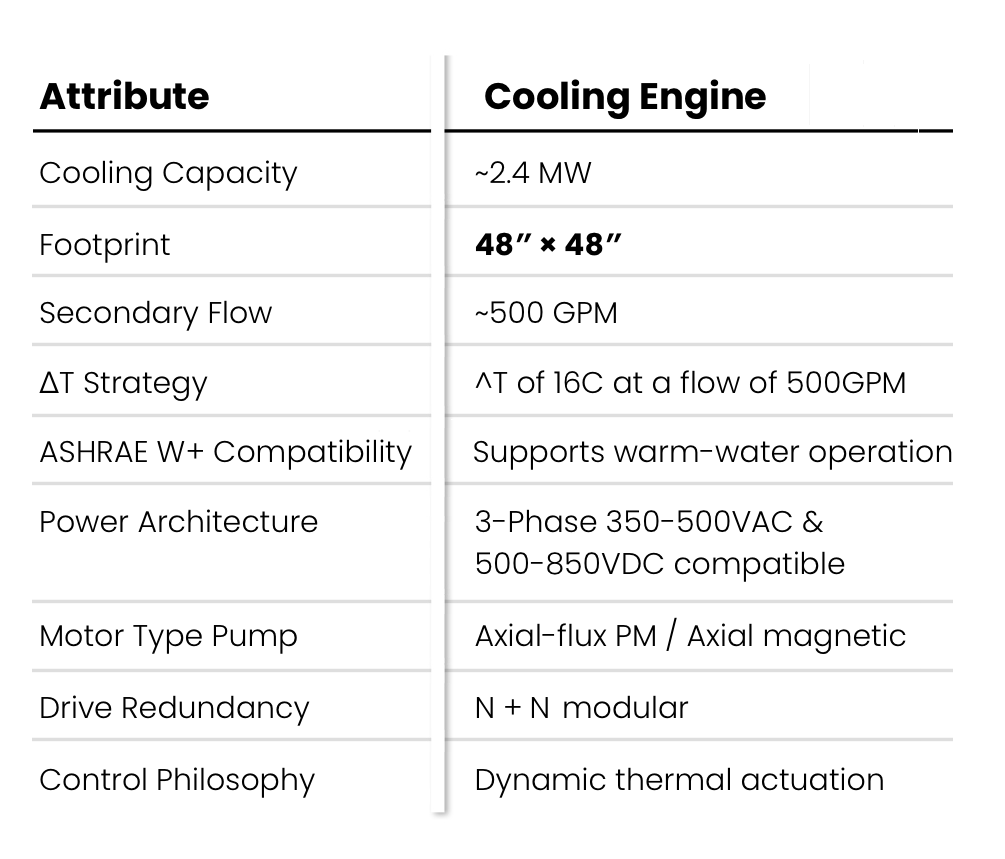

~500 GPM supports ~2 MW of cooling capacity

Reduced mass flow lowers pumping energy and piping requirements

Lower hydraulic inertia improves controllability and response speed

Thermal stability is achieved through speed and precision, not excess circulation.

N+N Redundant Architecture

Cooling Engine implements a true N+N redundancy model. Two completely independent motor-pump modules are each capable of supporting 100% of rated cooling capacity. Either module can carry full load continuously with no loss of performance, enabling uninterrupted operation under failure conditions and during maintenance events.

Redundancy model:

Two independent modules N + N, each rated for 100% of system capacity

Either module can operate as the sole active unit with no performance loss

Supports active-active load sharing or active-standby operation, configurable by system policy

Operational advantages:

Fast load transfer with no mechanical switchover hardware

Maintained full load operation for typical single module failures, within the N + N design envelope

reduced wear through partial load operation during normal use

Redundancy is achieved through modular control — not oversized standby hardware.

Thermal Stability as a Reliability Lever

By combining OCP-aligned interfaces with high-bandwidth pumping control, Cooling Engine helps:

Reduce temperature excursions during load transients

Limit thermal overshoot and undershoot

Smooth thermal cycling at the cold plate

These conditions are widely recognized as critical to long-term electronics reliability in high power AI systems— helping reduce unplanned downtime and extend component service life.

System-Level Performance Snapshot